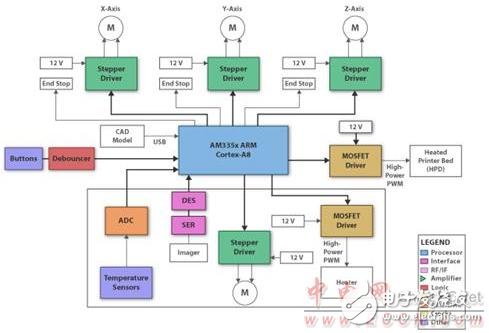

TI DLP 3D打印机总体解决方案采用DLP技术和Sitara AM335x ARM Cortex-A8处理器,本文主要介绍了DLP 3D打印机总体框图。

AddiTIve manufacturing, or 3D PrinTIng, is a process of laying down successive layers of material to produce a 3D physical object. In a matter of hours, 3D printers create products by “prinTIng” successive layers of material specified by the cross-sections of a Computer Aided Design (CAD) model. The possibilities for 3D printers are limitless as they have been used to create a wide variety of designs, from prototypes to end-products. With this technology, printing parts of a material can be done in a single process flow. Although they have been in existence for several decades, 3D printers are becoming more affordable for medium and small scale businesses in which rapid prototyping is brought all the way into the office, no longer requiring manufacturing floor space. The 3D printer model described below is especially useful for general purpose 3D printing. If high precision 3D printing is required, it is suggested to use a DLP 3D printer, which can be found under Similar End-Equipment Solutions.

The necessary components for designing a 3D printer using TI’s Sitara AM335x ARM Cortex-A8 processor are shown in the block diagram above. A 3D model of the object to be printed is produced by CAD software running on a PC. The CAD model is transferred to the processor via USB. The processor accomplishes motor control through Pulse Width Modulation (PWM) signals to MOSFET drivers. One option for hard real-time operation of the motors and extruders is to use the PRU-ICSS. The X- and Y-axis motors correctly orient the object on the Heated Printer Bed (HPB) while the Z-axis motor controls the extruder as it begins the process of printing layers of material. Fans may also be added for cooling the object as it is printed. Power is provided by TI Power devices.

图1。DLP 3D打印机外形图

图2。DLP 3D打印机总体框图

欢迎分享,转载请注明来源:内存溢出

微信扫一扫

微信扫一扫

支付宝扫一扫

支付宝扫一扫

评论列表(0条)